How TOFAŞ Saved €1.3M Annually by Automating Quality Control and Predictive Maintenance with KNIME

Summary:

The challenge:

- Monitoring spot welding processes manually was time-consuming and prone to errors

- Quality control delays pose risks to customer satisfaction and production speed

- Reactive maintenance led to high costs and downtime

The solution:

- Automated anomaly detection, defect classification, and predictive maintenance

- Used KNIME to integrate and analyze IoT sensor data and fault histories

- Applied deep learning and logistic regression to identify faults in real-time

The results:

- €1.3M+ annual cost savings across parameter tracking, quality control, rework, short stoppages, periodic maintenance, and energy optimization.

- 28 additional vehicles produced per day, directly boosting plant productivity.

- 2.9% increase in Overall Equipment Effectiveness (OEE), reflecting better utilization of resources and higher production efficiency.

- The solution has been recognized as best practice within parent company Stellantis, and a patent has been filed for the welding parameter traceability system without additional sensors.

- Enabled proactive maintenance across production lines, reducing potential downtime

- Significantly improved visibility, efficiency, and quality of the production process

Challenges: Manual Processes Slowed Quality Control and Increased Risk

TOFAŞ, a leading automotive manufacturer under the Stellantis umbrella, produces thousands of vehicles annually for various automotive brands, including Fiat, Citroën, Peugeot, Toyota, and Renault. In this high-volume manufacturing environment, quality control, especially in critical areas like spot welding, is essential to ensure safety and maintain customer trust.

Each car body contains approximately 4,000 welding points. Until recently, monitoring these welds relied on traditional methods that required engineers to manually collect and analyze data from multiple sources. This approach was not only labor-intensive and slow but also risked overlooking anomalies that could lead to costly quality issues or delays in production.

“The shift from reactive maintenance to predictive maintenance has helped us reduce unexpected downtime and improve production continuity. KNIME made it easier for us to combine data from different sources and build models that support timely interventions.” Melike Gülşen Toksöz, Specialist Data Scientist at TOFAŞ

The lack of a centralized monitoring platform and the absence of predictive maintenance created a reactive environment, where problems were often only addressed after they impacted operations, leading to increased downtime, higher maintenance costs, and quality assurance bottlenecks.

Solution: From Reactive to Proactive with KNIME

TOFAŞ turned to KNIME to address these challenges and create a centralized, automated system for monitoring spot welding parameters.

The team integrated data from IoT sensors across production lines, along with historical fault records and detailed process data. This data was collected on a big data platform and analyzed in KNIME, where workflows were built to detect anomalies and classify defects.

Deep learning and logistic regression models helped detect real-time production issues, and time series forecasting helped the team anticipate potential failures. These models supported predictive maintenance processes that allowed engineers to intervene before breakdowns occurred, reducing bottlenecks and preventing downtime.

“KNIME’s flexibility allowed us to integrate with our existing systems and quickly set up automated processes for quality control. This significantly reduced manual work and enabled faster, data-driven decisions on the production floor.” Melike Gülşen Toksöz, Specialist Data Scientist at TOFAŞ

TOFAŞ also automated specialized quality assurance tasks, previously done manually, like sharp burr classification and defect-type labeling, which made quality checks faster and less repetitive for the team.

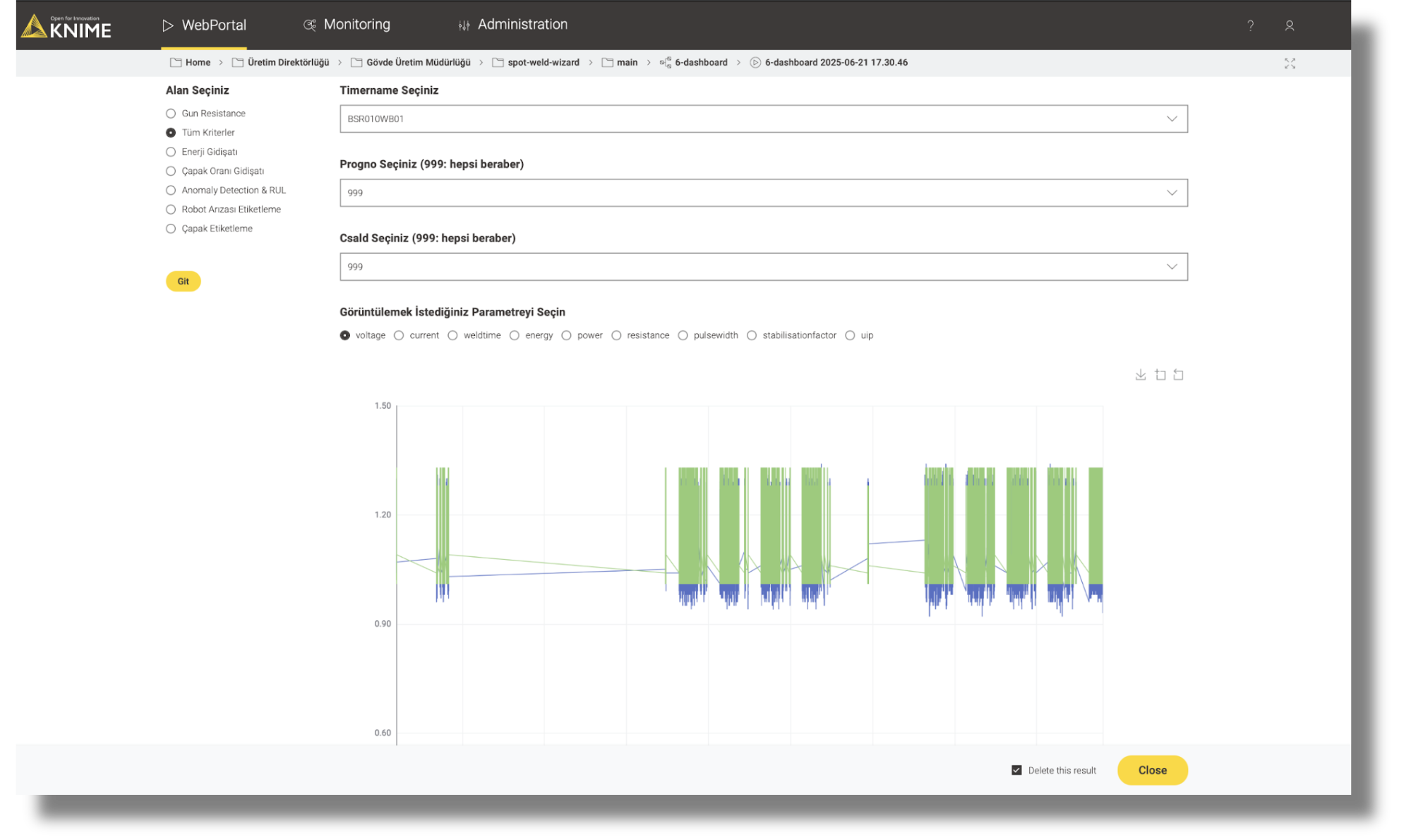

The entire solution was deployed using the KNIME and Data Apps. TOFAŞ used data apps to create visual dashboards, data entry forms, and monitoring pages that allowed cross-functional teams to interact with results, validate predictions, and make quick decisions, all through a simple web interface.

“KNIME helped us bring advanced analytics closer to our production operations. Our teams can now interact with data models and dashboards directly, making analytics an integral part of daily manufacturing activities.” Melike Gülşen Toksöz, Specialist Data Scientist at TOFAŞ

KNIME Data App used by TOFAŞ for real-time monitoring of welding parameters, enabling cross-functional teams to analyze anomalies and validate predictions through an interactive web interface.

KNIME Data App used by TOFAŞ for real-time monitoring of welding parameters, enabling cross-functional teams to analyze anomalies and validate predictions through an interactive web interface.

Results: Speed, Efficiency, and Quality Gains

Since deploying the KNIME solution, TOFAŞ has seen measurable improvements in output, speed, and lower costs across its welding processes.

- Downtime reduction: Short stoppages were reduced, contributing to €193k in annual savings, while production line interruptions were minimized through predictive maintenance.

- Error reduction: Earlier detection of welding anomalies helped avoid costly rework, supporting €435k savings in quality control and €265k in rework-related costs.

- Maintenance cost savings: The predictive maintenance system reduced periodic maintenance costs, delivering €58k in annual savings and improving equipment longevity.

The automated system reduced the time and resources needed for defect detection and analysis. Quality issues are now caught earlier, reducing material waste and production delays.

Beyond welding, TOFAŞ plans to use this approach with other robots in the body shop and eventually extend it to other production areas. Existing infrastructure and analytics workflows can now be repurposed or adapted by other teams without needing extensive new development.

TOFAŞ is now focused on optimizing its deep learning models and testing their validity through controlled error simulations. Once verified, these predictive maintenance and quality control solutions will be expanded to cover all body shop robots, with plans to roll out similar systems across the broader factory.

Why KNIME

TOFAŞ chose KNIME for its open-source model, easy connection with existing systems, and its ability to adapt to different use cases. KNIME enabled TOFAŞ to build predictive models suited to production needs using both code-based and visual workflows. Direct connectivity with cloud platforms like Azure and external tools such as Python provided the performance and capacity needed for factory-wide analytics.

“This project taught us that successful digitalization is not only about technology, but also about collaboration between teams and making data accessible at every level of the organization. KNIME helped us bridge that gap effectively.” Melike Gülşen Toksöz, Specialist Data Scientist at TOFAŞ

From a business standpoint, KNIME offered a cost-effective and low-risk entry into data projects at scale. Accessible visual workflows allowed non-technical users to engage with data, and the support from the KNIME team made it easier for teams to get started quickly. Quick setup and the ability to expand made KNIME a good fit for TOFAŞ’s digital transformation goals.

Learn more about KNIME Business Hub and how it can help your organization, or schedule a demo with our customer care team to see how it works in practice.

This Success Story is available here as a PDF.