In this blog post Brendan Doherty discusses the processes and steps he took on the journey to embed KNIME in a High Volume Manufacturing Environment within Seagate Technology through a data literacy program.

Seagate Technology is one of the world's largest manufacturers of electronic data storage technologies and solutions. They create products and services that include network attached storage, high performance computing, data protection appliances, internal hard drives, backup and recovery services, flash storage, and more. A vertically integrated company, Seagate has manufacturing plants in over ten locations worldwide. There are many different groups in multiple locations all using data from different sources and in different formats - all on a daily basis.

KNIME was recognized as an appropriate tool for beginners and experts alike. Beginners benefit from a no-code introduction to advanced data science, while experts can leverage low-code to reach out to all the techniques they know and love.

Here’s his own account of this journey:

The Goal: Make Better, Data-Driven Decisions Across Global Sites

The Operations Technology Advanced Analytics Group (OTAAG) recognized the potential of using KNIME Analytics Platform in the data-centric world in which employees work. The goal: make better, data-driven decisions as well as automate repetitive manual data tasks at various sites around the world (US, Asia, Europe). After having used KNIME for a range of projects for approximately one year I attended the KNIME Summit in Berlin. I was enthused from this experience and from seeing how other companies were using KNIME. So I developed a pathway to advocate the use of KNIME in manufacturing and embed it within the plant and other Seagate sites.

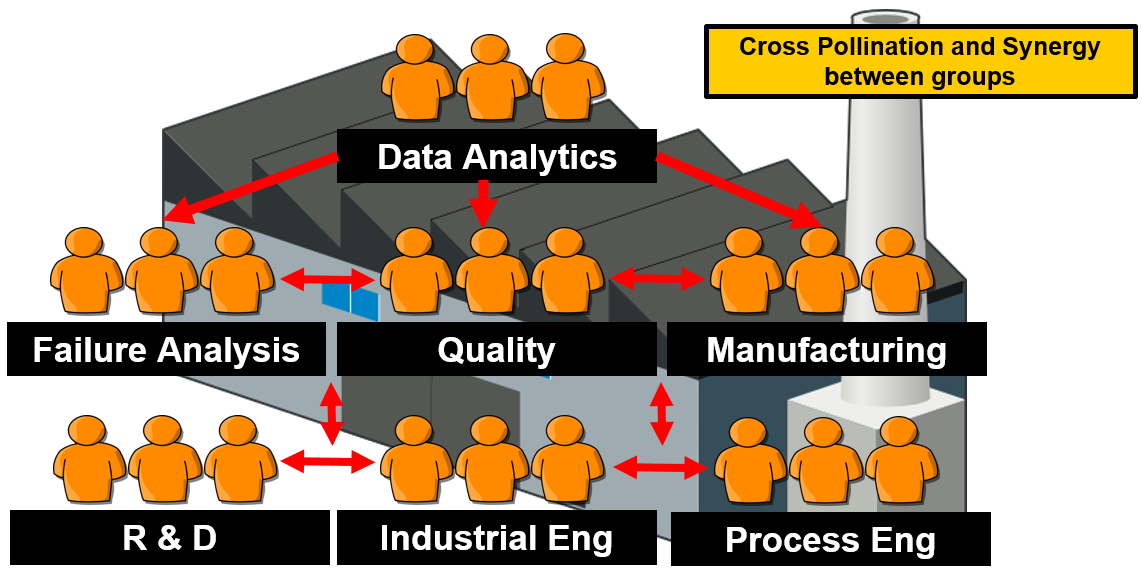

Initially there were only a few users all based within the OTAAG group. But now, after hard work and persistence, all major and many smaller groups in the factory are showing varying levels of KNIME usage for a variety of data tasks. The aim now is to encourage cross pollination and synergy between groups, where users exchange concepts and knowledge, with the goal of benefiting them and the company (Figure 1).

The Requirement: Find a Tool for All Users to Achieve Data Engineering Needs

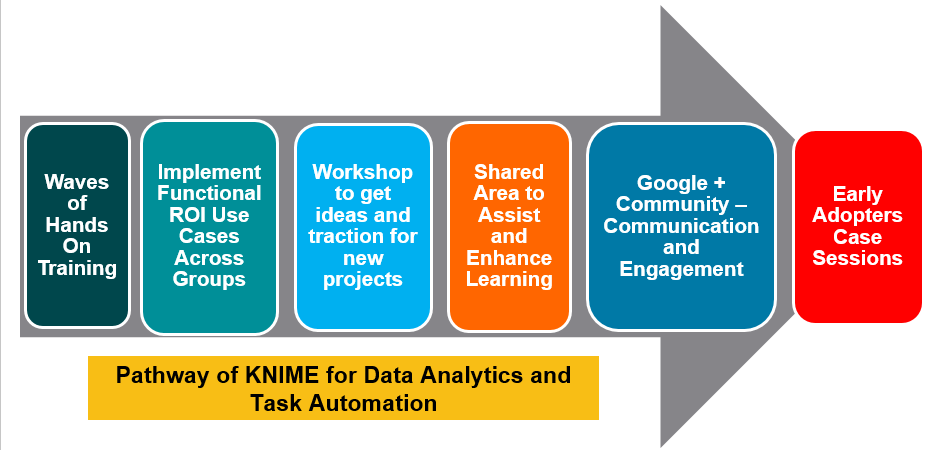

Some of the steps implemented to enable the uptake of KNIME are shown in Figure 2.

Before the project started, there was a keen interest from a range of groups within Seagate to learn more about data engineering and data science. But due to varying levels of user experience and ability this ambition hadn’t been achieved. However, having previously programmed in many languages, I saw the opportunity to advocate the use of KNIME as a tool for users of all levels to engage with and enable them to achieve their data engineering needs. It was the low-code aspect of KNIME that made me realize it could be possible to move forward and teach these non-data-scientist individuals how to realize their ambitions.

The first step was to deliver hands-on KNIME training to many users across a range of groups. By using specific factory-orientated examples, which catered to all levels, people could immediately see the benefits and opportunities of using the tool. The training was pitched at a pace and level so that non-native programmers could easily follow and understand the examples without feeling overwhelmed.

Once the training was complete, people were encouraged to complete a use case based on their own job function. An enthusiastic approach is critical here. I worked with many users on a one-to-one basis to get projects kicked off and completed, which, in the long run, benefited both the users and the company. Most users were able to get up and running quickly after the training - in many cases within a week or two.

The Result: Users Create Solutions to Daily Problems Quickly and Easily with KNIME

Here are two concrete examples of what was achieved with this data literacy program:

An intern with limited programming skills was able to get up to speed with KNIME very quickly, and saw an opportunity where they could employ their newly learned skill set. They created a solution, which highlighted tools that were not following complex dispatch system rules, thereby having knock on effects in the manufacturing line. By highlighting affected tools and taking corrective action, the speed at which material was moved improved and the manufacturing cycle time was decreased. The new solution enabled both Seagate and the intern to achieve a quick return on investment: faster time to solution, and new skills learned.

Once an engineer had completed some hands-on training, they saw the potential to automate a very time intensive task. Previously this involved a rotating list of engineers having to trawl through multiple Google documents and databases on a daily basis to compile a document that identified which products were on hold in the manufacturing line. The factory is highly integrated with Google tools, and the KNIME Google API Integration has been extremely beneficial. With KNIME, this automated solution now saves around 90 hours of engineering time per month. The new solution also reduces cycle time by letting staff tackle products in a hold state as soon as they come into the office each day, rather than waiting for a report to be compiled and sent.

Data Literacy Program Increased Motivation to Use Data Analytics in Other Manufacturing Use Cases

A shared area and Google+ site where KNIME users could communicate and share useful documents and suggestions was set up with the objective of increasing engagement and communication with the growing KNIME community.

Once a critical mass of manufacturing use cases and users had been reached, early adopter sessions were held where users presented the solutions they’d created to other colleagues. This word of mouth advertising helped gather traction from people who had previously not engaged in using KNIME.

At KNIME Spring Summit 2018, Allan Luk and Eric Lin presented the Citizen Data Science Program, which they were rolling out. An important element of this is using KNIME for Guided Analytics. This initiative dovetailed well with embedding KNIME in the Seagate factory.

Now Empowering all Users to Discover and Apply Machine Learning in Manufacturing

There are now many people using KNIME at Seagate - also beyond manufacturing use cases - which has worked well with the Citizen Data Science Program. It’s empowered people who previously may have not considered the discovery and application of machine learning techniques to dip their toes into the world of data science!